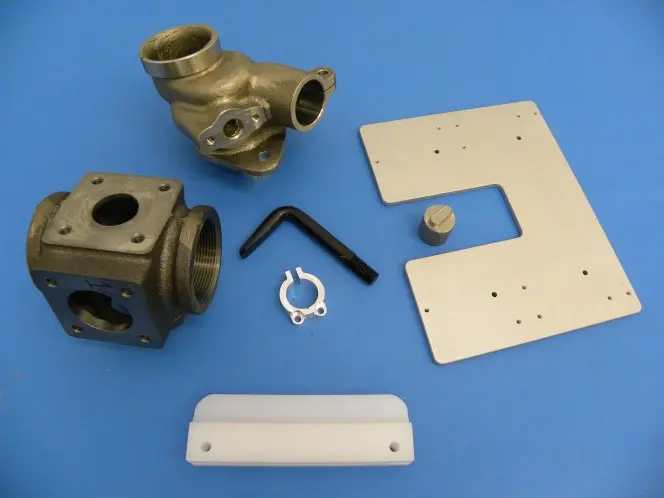

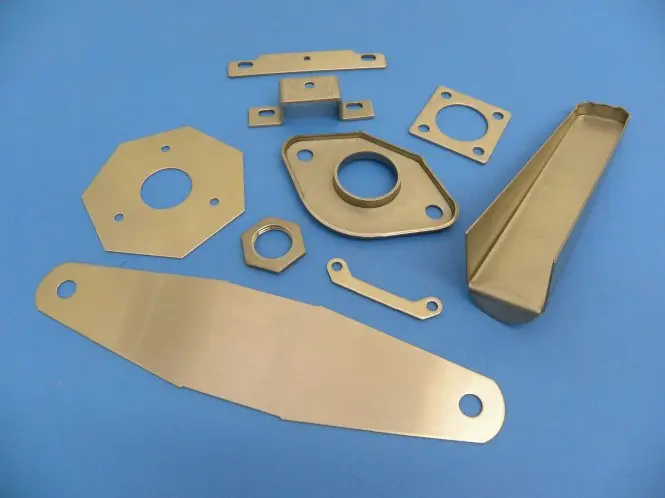

Morgan Manufacturing, Inc. provides up to 5-axis turn-mill, CNC vertical milling with indexer, precision turning, machined cast parts, and stamping services.

We offer our services across Petaluma, Santa Rosa, Windsor, Healdsburg, Oakland, San Francisco, Sunnyvale, San Jose, Hayward, Fremont, Santa Clara, Cotati, Sacramento, Fairfield, Richmond, Cupertino, Redwood City, Morgan Hill, and Milpitas.